Therefore, all dimensions shown 5-1/2" will not require cutting. If a board other

than 5-1/2" wide will require additional cuts.

STEP #1

Make (2) side wall panels as shown in Figure #1.

STEP #2

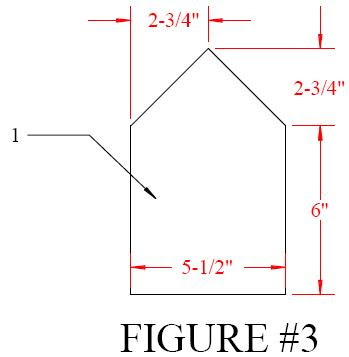

Make (1) front wall panel as shown in Figure #2.

Make (1) back wall panel as shown in Figure #3. Use front panel as a template for back panel to ensure both panels are identical.

Assemble (2) sides, front, and back panels as shown in Figure #4. Glue and nail (3 nails per joint) each joint.

Make (1) bottom panel by placing assembled walls on top of oversized, future bottom panel, board as shown in Figure #5. Mark (2) edges to be cut from inside of birdhouse as shown in Figure #5. Cut on marked lines. Install bottom panel inside assembled walls with glue and nails (2 nails per side).

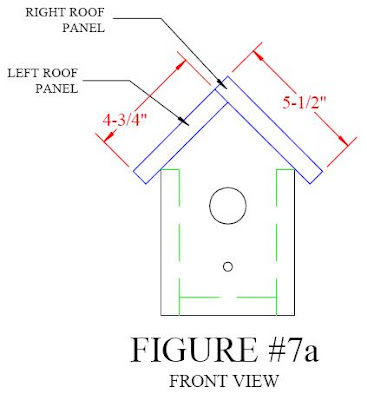

Make (1) right roof panel and (1) left roof panel as shown in Figure #6a and Figure #6b.

STEP #7

Install roof panels on house walls as shown in Figure #7a and Figure #7b. Glue and nail (2 nails per end and 3 nails along ridge) roof panels.

STEP #8

Cut a 4" long piece of 3/8" diameter wood dowel. Glue and insert dowel into 3/8" diameter hole previously cut into front panel of bird house.